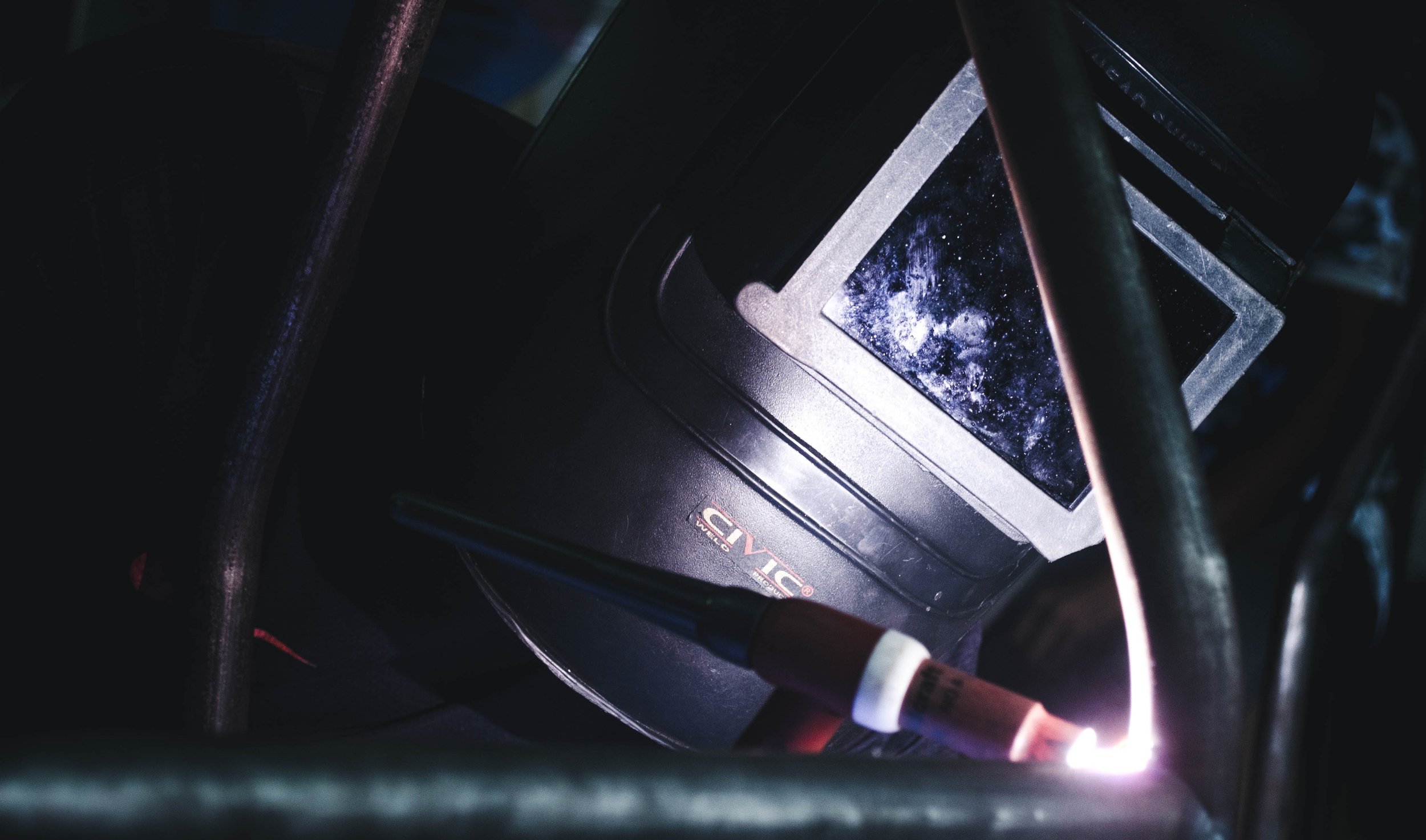

Robotic & Automated Welding

When ultra-precise, programmable welding is required, Projects utilizes advanced manufacturing techniques such as robotic welding or auto-welding machines to accomplish these tasks.

Robotic and automated welding are advanced manufacturing techniques that have transformed the welding industry, providing high precision and accuracy in the welding process. When ultra-precise, programmable welding is required, Projects Inc. utilizes these techniques to accomplish these tasks efficiently and effectively.

TRUSTED BY

Our Welding Services

Robotic Welding

Robotic welds are conducted with an ABB IRB 1520ID 6-Axis Robotic Arm with an ABB IRBP 250A Positioner.

This is capable of 8-Axis MIG welding with a 4′ x 3′ x 3′ working volume.

Automated Welding

Automated weldings are conducted with our AWS-150 Automated TIG Welding System which produces, precise and highly repeatable welding results. This provides us high-quality, low-cost manufacturing solutions for industrial and commercial aerospace industries.

Robotic vs Automated at Projects Inc

For Robotic

Robotic welding involves the use of robotic arms to perform the welding process, which are programmed to follow a pre-determined path. The machines can be set to make consistent and repeatable welds with high precision, accuracy, and speed, making them ideal for large production runs where consistency is essential. This method of welding allows for greater control over the welding process and ensures a uniform quality of the welded joints.

For Automated

Automated welding machines, on the other hand, are designed to perform welding operations without human intervention. These machines are ideal for welding complex parts that require high accuracy and precision, where consistency and quality are critical. They can be programmed to perform a wide range of welding tasks, making them versatile and efficient. Automated welding machines can handle large volumes of work, reducing production time and costs significantly.

Overall, robotic and automated welding techniques offer several benefits over traditional welding methods, including higher precision, accuracy, and repeatability, faster production times, and greater consistency in the quality of the welded joints. By utilizing these advanced manufacturing techniques, Projects Inc. can ensure that the welding process is performed with maximum efficiency, accuracy, and reliability, delivering superior quality products to its customers.